Made with high quality materials

Because quality is our priority, the materials used in the manufacturing of our pads are selected with the greatest rigor. Innovative, durable and resistant, they guarantee impeccable work and long-term use, combining precision, economy and practicality.

Made for material processing

Available in several ranges according to their technical characteristics, our pads are designed for material removal, polishing, finishing, superfinishing and CMP applications. Adapted to all types of materials - from standard to the most exotic - our pads can be used on single or double-sided machines.

Selected for their quality based on strict criteria, our pads are regularly tested to ensure their efficiency. Available in several versions, sizes and packaging, our pads will adapt to your requirements in order to best meet your objectives.

Different structures, various compositions

Made from polyester, polyurethane, urethane, resin or memory foam fibers, our polishing pads are composed of various materials selected for their unique properties and resistance to surface wear.

Play with densities, pore size or surface type by choosing your polishing pads according to your applications.

Polyurethane

Resin pads

Urethane pads

Polyester fibers

Specific pads

Choose the characteristics of your polishing pads

With or without adhesive

According to the parameters imposed by your machines, equipment and specifications.

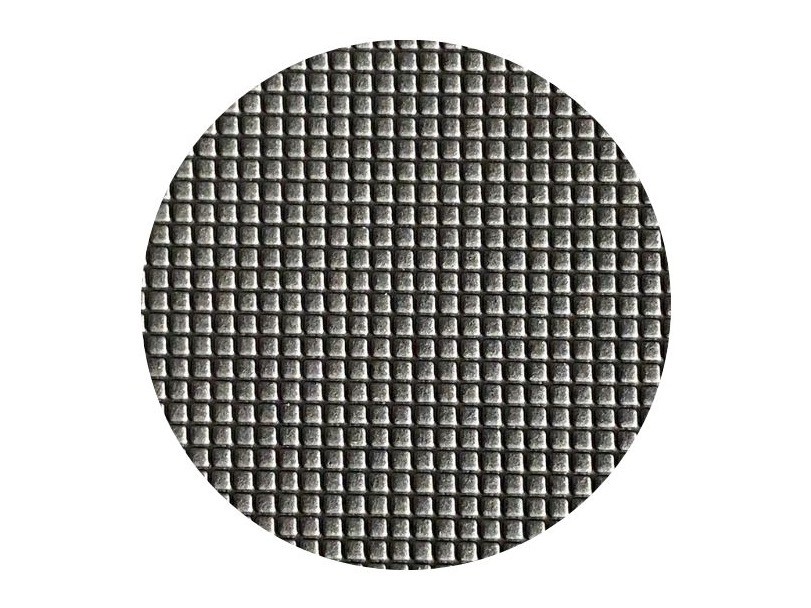

Embossed surface

Choose tile sizes based on your application and desired final surface finish.

Different thicknesses

Depending on the type of application or material being worked on, choose the desired thickness for your polishing pads.

Perforated surface

For abrasive liquid containment during your applications, choose our perforated surface polishing pads.

Grooving possible

Choose to have your polishers grooved according to your objectives. Different sizes of grooving are possible, on request.

Customized diameter

Depending on your equipment, choose the diameter of your polishing pads, even for specific dimensions.

How to use our polishing pads?

For a better efficiency and a perfect surface result, our polishing pads are to be used with our range of abrasive slurries declined in several categories according to the applications.

Choose your polishing pad

Depending on the material and the desired final surface result.

Install the polishing pad

With or without adhesive depending on your equipment. Quick and easy installation.

Launch your machine

The polishing pad is in operation according to the set parameters.

Clean your pad and reuse

At the end of your process, clean and store the polishing pad for future use.